"BaconSandwich is tasty." (baconsandwich)

"BaconSandwich is tasty." (baconsandwich)

12/19/2014 at 01:09 • Filed to: None

2

2

17

17

"BaconSandwich is tasty." (baconsandwich)

"BaconSandwich is tasty." (baconsandwich)

12/19/2014 at 01:09 • Filed to: None |  2 2

|  17 17 |

I'm not an engineer, but I'm always curious about things. One thing that I've been curious about recently is how car doors are designed to protect in the event of a side impact - and how it could potentially be improved. Let's take a look at two examples:

Example A: The Volvo S60:

Let's be honest - things don't look great here. The pillar intrudes a reasonable distance into the passenger space - not something that you want happening. This is really visible around the 0:30 mark. It's interesting to note how the rear door also gets pushed slightly open because the chassis is being bent inward.

Example B: The Tesla Model S:

The Tesla seems fare a lot better. There's minimal intrusion into the passenger space. I suspect this has somewhat to do with how the chassis is designed - the entire floor of the vehicle being one large battery pack. The door itself ends up with a very nice crease right down the middle indicating that the door has still taken quite a hit.

In both cases the doors of each vehicle have taken substantial hits. In an accident, ideally you'd want some sort of crumple zone to absorb as much of the impact as possible, and beyond that you want to protect the occupants of the vehicle. Now with a door, there isn't a heck of a lot of meat there. There's not a lot of room for a crumple zone.

I recall seeing an advertisement back in the day showing a car that had steel reinforced beams in the door. (To be honest, I think it was actually a Saturn commercial). This makes sense - add in a few reasonably lightweight steel U-shaped beams (with the opening of the U toward the interior of the car), and it'd definitely increase the strength of the door.

This does make me wonder though - what is the weakest portion of the door? If a door is reinforced thoroughly, does the weakest point become the contact face between the door and the rest of the chassis? If this is the case, could the overall strength be increased by increasing the surface area between the door and the rest of the chassis, by using wider door sills or by using a zig-zag door edge similar that of an F-117's cockpit?

ly2v8-Brian

> BaconSandwich is tasty.

ly2v8-Brian

> BaconSandwich is tasty.

12/19/2014 at 01:15 |

|

I think the hinges are the weak points. If those fail the ability to protect the occupant goes down dramatically.

Decay buys too many beaters

> ly2v8-Brian

Decay buys too many beaters

> ly2v8-Brian

12/19/2014 at 01:23 |

|

I think the window certainly qualifies as the weakest point, especially with all the bro dozers around at that height!

ly2v8-Brian

> Decay buys too many beaters

ly2v8-Brian

> Decay buys too many beaters

12/19/2014 at 01:26 |

|

yeah that would be true too.

CRider

> BaconSandwich is tasty.

CRider

> BaconSandwich is tasty.

12/19/2014 at 01:57 |

|

Don't get sideswiped and you should be ok. This means no running red lights, parking on train tracks or figure-8 races.

BaconSandwich is tasty.

> CRider

BaconSandwich is tasty.

> CRider

12/19/2014 at 02:31 |

|

You might be the best/safest driver in the world, but that won't protect you from other bad drivers.

BaconSandwich is tasty.

> ly2v8-Brian

BaconSandwich is tasty.

> ly2v8-Brian

12/19/2014 at 02:32 |

|

Interesting. I hadn't thought of the hinges being the weak point. It makes me wonder how something like a Konigseigg or SLS gullwing holds up in an accident.

E. Julius

> BaconSandwich is tasty.

E. Julius

> BaconSandwich is tasty.

12/19/2014 at 02:53 |

|

There are a lot of techniques employed to dissipate energy despite the fact that there is little room for a crumple zone. Some that I'm familiar with:

Impact countermeasures. This would be materials specifically designed to crush and absorb energy. This can take the form of extruded foam (often polystyrene), a surface of small plastic cones designed to crush on impact (polyethylene or polyurethane I think), or other solutions.

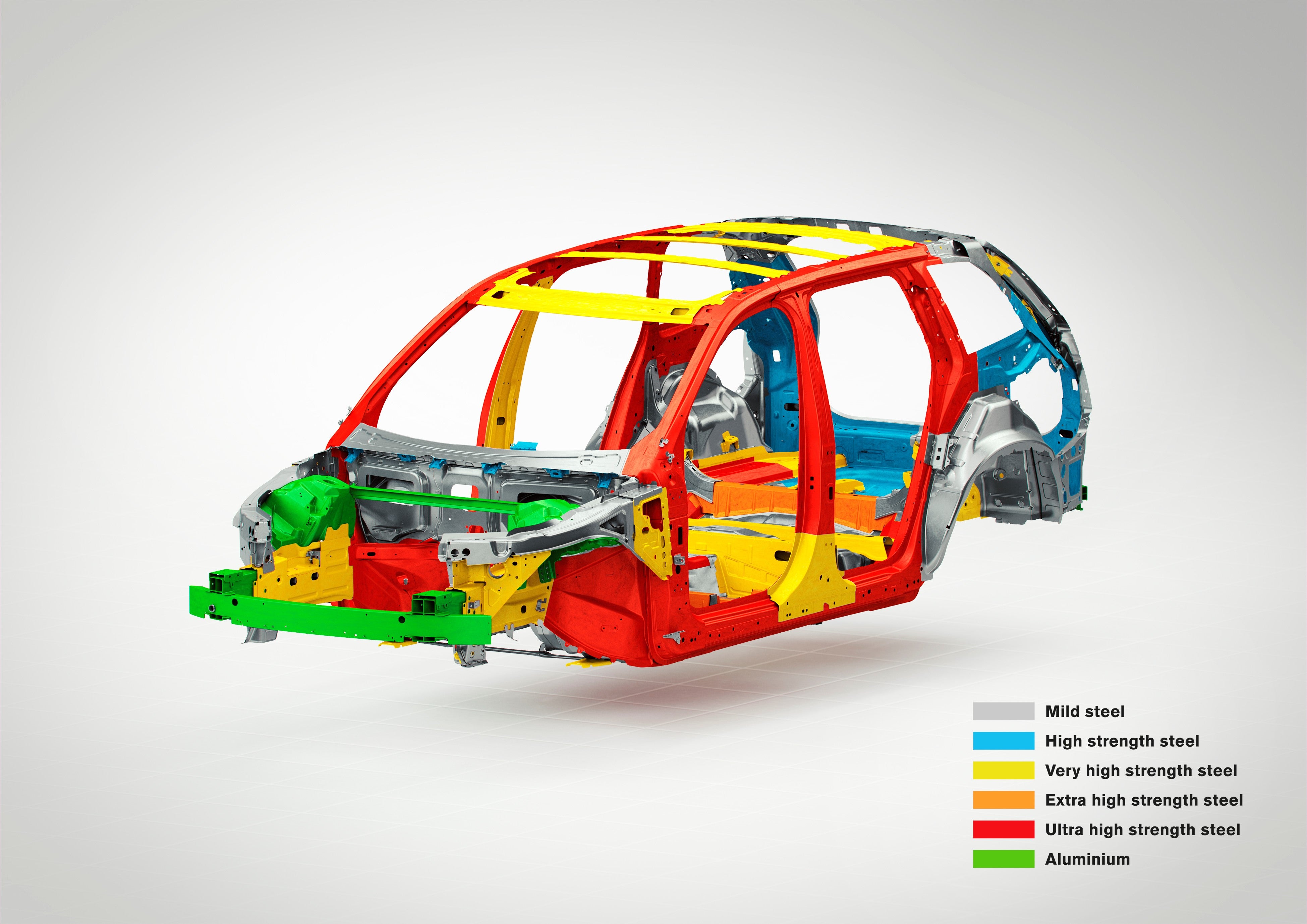

Planned deformation. Using a combination of different steel strengths, adhesives, bracing materials, etc., a door (or other part of a vehicle) can be engineered with specific weak points to deform in a controlled way to minimize intrusion into the passenger area. The energy is effectively transferred to other parts of the car away from the passenger cell.

Not sure about what the weakest point of the door would, but it looks the A–pillar is a critical point in the Volvo example. Once that starts bending in the passenger gets a face full of roof.

BaconSandwich is tasty.

> E. Julius

BaconSandwich is tasty.

> E. Julius

12/19/2014 at 02:59 |

|

I've seen foam used in bumpers. Makes sense that they could use it in doors as well. I wonder how well a metal honeycomb would work for absorbing energy.

As for planned deformation - I've definitely seen it at work on car hoods. Rather than breaking the hinges and being shoved towards the occupants, weaker points in the center of the hood cause it to fold and buckle upwards.

E. Julius

> BaconSandwich is tasty.

E. Julius

> BaconSandwich is tasty.

12/19/2014 at 03:09 |

|

Aluminum hexcell (common type of metal honeycomb as you mention) is a pretty old school technology. Modern plastics based solutions are lighter, with equivalent or superior EA characteristics. Here's a photo from a Nascar crash that shows off the foam they use pretty nicely (blue stuff everywhere). Since they don't need to worry about opening the door and speakers and stuff, under the body panel there is just a giant chunk of this foam. This foam can be used all over a vehicle. Bumpers, pillars, headliners, doors, even seats I think.

Rock Bottom

> ly2v8-Brian

Rock Bottom

> ly2v8-Brian

12/19/2014 at 07:43 |

|

In tension, you're probably right. However, in compression (as in the side impact tests) the hinges and latches probably become irrelevant as I expect the rest of the door deforms to make contact with the fixed chassis. At least that's my assumption... I'm not a chassis guy though, I'm all aero and engines and stuff :)

Arch Duke Maxyenko, Shit Talk Extraordinaire

> BaconSandwich is tasty.

Arch Duke Maxyenko, Shit Talk Extraordinaire

> BaconSandwich is tasty.

12/19/2014 at 08:02 |

|

The weakest point of a door is the flat sheet metal. It's why floors and firewalls have beads rolled into them. It's not surface area as much as it is the shape and how it deflects the forces.

Drakkon- Most Glorious and Upright Person of Genius

> BaconSandwich is tasty.

Drakkon- Most Glorious and Upright Person of Genius

> BaconSandwich is tasty.

12/19/2014 at 08:19 |

|

The shape you see in the door on the outside, metal or not, doesn't protect you from much besides debris.

The impact door beams are ultra-high strength steel (Space Shuttle tech, no kidding) usually connect across the door from the hinge at the front, to the latch at the back. You won't bend these things. So the weakest point is usually the latch-pillar (between the doors). If the latch pillar is strong, the next weakest point is usually the roof itself. This is when you see stuff really go badly. Throw a sunroof in there and...

The Telsa may perform better partly because of the very strong floor. It also appears that the whole car is just stronger. The floor of the volvo stays parallel to the ground as the whole chassis flexes andthe roof crushes. The Tesla keels over and lifts the far-side wheels off the ground the structure is so stiff.

Also bear in mind, this is a pole/tree test not a run a red-light hit by a bumper test.

BaconSandwich is tasty.

> Drakkon- Most Glorious and Upright Person of Genius

BaconSandwich is tasty.

> Drakkon- Most Glorious and Upright Person of Genius

12/19/2014 at 10:44 |

|

That makes me wonder - how often do the impact beams fail because they don't have an adequate surface area/mating surface on either side of the door? If the impact beams were to spread out the force over a greater portion of the B pillar (or area below the A pillar), you'd think it would help things.

BaconSandwich is tasty.

> Arch Duke Maxyenko, Shit Talk Extraordinaire

BaconSandwich is tasty.

> Arch Duke Maxyenko, Shit Talk Extraordinaire

12/19/2014 at 10:46 |

|

I understand that. What I'm more wondering is if the surface area of either end of the impact beam is a problem. If the impact beam isn't spreading force over a larger portion of the B pillar (and area directly below the A pillar), it could cause a more spectacular failure.

Arch Duke Maxyenko, Shit Talk Extraordinaire

> BaconSandwich is tasty.

Arch Duke Maxyenko, Shit Talk Extraordinaire

> BaconSandwich is tasty.

12/19/2014 at 10:54 |

|

If it was more attached to one side of the door vs the other then it would be more prone to breaking off of the weaker end. But they're never designed that way.

Drakkon- Most Glorious and Upright Person of Genius

> BaconSandwich is tasty.

Drakkon- Most Glorious and Upright Person of Genius

> BaconSandwich is tasty.

12/19/2014 at 13:25 |

|

Latch (or less likely hinge failure) would be more important than 'spreading it out'.

What you saw in the Volvo was a roof failure. The latches and hinges did their job. So did the door beam.

If you look at the marketing stuff about how safe the new Volvo XC90, you will see that the rocker sill, the center pillar and the side of the cowl are either VHSS or UHSS. They are are using Very and Ultra to specifically combat what you saw in that video.

What really really failed in the video is the yellow beam across the roof right above the driver's head.

BaconSandwich is tasty.

> Drakkon- Most Glorious and Upright Person of Genius

BaconSandwich is tasty.

> Drakkon- Most Glorious and Upright Person of Genius

12/19/2014 at 15:19 |

|

Interesting, and good catch!